QUALITY CONTROL

QUALITY COMMITMENT

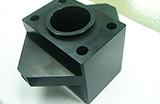

Quality is our #1 priority at Aohong. When working with us, you will quickly learn that quality is what separates us from our competitors. Aohong requirements and expectations and provide on-time delivery of defect-free precision machined parts, castings, forgings, fabrications, and specialty hydraulic.

Aohong’s commitment to continuous improvement means great value is placed on teamwork, education, training, and prevention-oriented techniques across all possible aspects of company operations.

Give us a chance, we will give you a surprise!

QUALITY ASSURANCE

As an ISO 9001 certified company utilizing ISO certified suppliers, our customers rely on us to deliver world class quality products. Our standard operating procedure for all customers incorporates the automotive PPAP (Production Part Approval Process) quality system for part qualification.

Our in-house quality assurance technicians verify every lot of parts to ensure it meets our customers’ high standards. We utilize accredited independent labs to certify material, finish, heat treatment, coatings, customer specific performance and test requirements, and specifications.

QUALITY COMPLIANCE

Aohong incorporates a robust quality plan to inspect and verify every lot. As an ISO 9001 certified company, our in-house quality assurance professionals maintain the high standards of training and education. Every lot that comes in to Aohong is segregated until all material and dimensional inspections have been completed and certified.

Possessing the latest in inspection technology and precision metrology, our quality team is able to obtain extremely accurate data and pass that information on to our customers whenever required. We offer our customers: First-Article Inspection Reports,PPAP Reports and Final Inspection reports. We also maintain a database with a full complement of quality records for immediate retrieval when required for warranty.

Aohong’s in-house inspection capabilities include mechanical inspections using the art CMM, (coordinate measuring machine), hardness testing, thread gauging, electronic document control, digital calipers & micrometers, lot traceability, process capability studies, gauge R&R studies and inspection accuracy to 0.00005″ (0.001mm).

Our Calibration Program assures Aohong’s metrology is functioning properly and kept in compliance both in-house and at our partners. We continually monitor all associated metrology and gages in all of our production facilities.

Our certified outside test labs perform the full gamut of testing such as Physical Property Testing, Destructive & Non-Destructive Testing, X-Ray and Metallurgical Analysis, Corrosion Resistance (salt spray) testing of coatings, and virtually any test required by our customers.

AOHONG MACHINERY

As an ISO 9001 certified company, our in-house quality control

department ensures that all products meet or exceed our customers’ highest expectations.